Utilising the perfect pick process your customer orders in record time. User currently fulfil orders in approx. 15 minutes of it being released for picking.

Achieve rates of up to 500 lines per person and up to 1000 lines per aisle with the Perfect Pick system

With the largest tote available in the market (760mm x 508mm x 200mm/250mm/300mm/350mm and divisible up to 12 cells per tote, the Perfect Pick system allows users to store more goods on a smaller footprint.

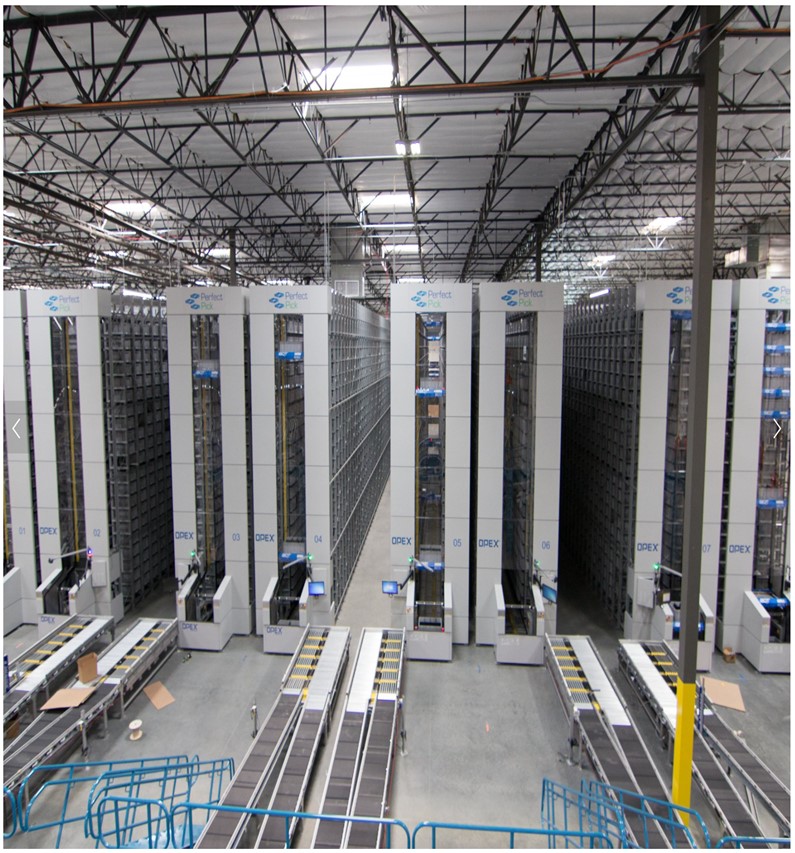

A Perfect Pick aisle is comprised of modular, high-density racking along with a fleet of autonomous robotic delivery vehicles, iBOTs®, which can access every storage location within their aisle – both horizontally and vertically. iBOTs deliver inventory directly to a workstation located at one or both ends of the aisle. This direct interface eliminates the need for complicated conveyor systems or transfer equipment, such as elevators or lifts, which add complexity to the system. Perfect Pick’s traffic control software monitors the position of all order picking robots in the aisle and directs their movements to ensure full resource optimization and operational efficiency.

The Perfect Pick solution, unlike other solutions, is a self-contained, standalone point solution that provides a secure location for storing inventory as items can only be accessed by an operator using the system, tracking inventory data in real-time.

Smarter Automated Solutions can provide a complete software solution to implement a Perfect Pick

Click here to find out more